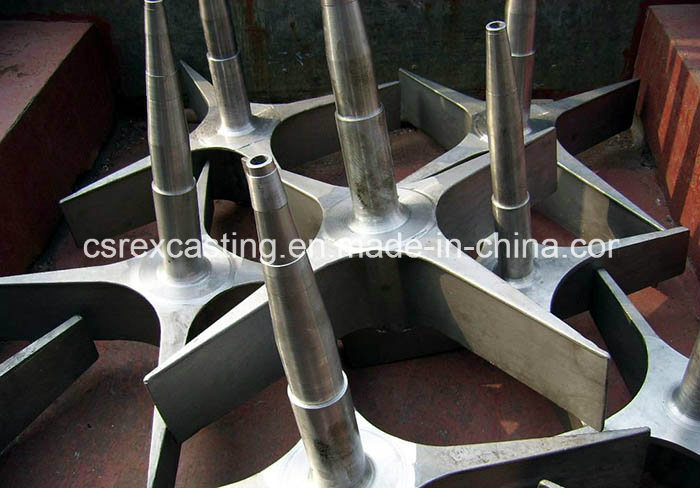

Investment castings according to Customer`s requirments

We can offer you investment casting parts, railway casting parts, railway parts, excavator machinery parts, mining machinery parts, engineering machinery, agricultural machinery parts, sand casting, bucket tooth, auto parts, stamping & forging, and valve parts. We are capability in manufacture non-standard metal machining.

Material: Carbon steel, low alloy steel, stainless steel

Length Capacity: 10mm-1000mm

Weight: 0.5-150KG

Certificate: ISO9001: 2008

Main market: North America, South America, Eastern Europe, Africa, Western Europe etc.

Packing: Bubble bag, carton, wooden box

Tolarance: ISO/GBCT7-9

Casting standard: ISO, DIN, GB, AAR, BS

Sample leadtime: 30-60days

Inspection equipment: Metallographic analyzes, magnetic particle inspection machine, optical spectrum analyzes, X-ray, impact testing machine, universal strength tester, hardness tester, three coordinates detector, etc.

1. Most competitive price with the best quality

2. Short delivery time

3. Produce according to the special requirements of the customers'

One-Stop OEM service based on drawings or sample

Process |

sand casting, and investment casting |

Production capacity |

1.sand casting is around 2000 tons per month.

2. investment casting is around 120 tons per month |

Advantage |

produce goods according to the drawings or samples,

even very complicated structure |

1.We took lead in passing ISO 9001 in 1998

2.Our QC 16 staffs with at least five years experience

each check every piece carefully. |

Size can offer |

Investment Casting: The minimum casting space available

is 0.75mm, and the thinnest is 0. 15mm. The longest blind

hole (diameter 30mm) we can make is 170mm. We also have

various inspection facilities which can do micro organ and

mechanics test.

Sand Casting:0.02-15KG

|

Material |

Investment Casting:201, 202, 303, 304, 304L, 316, 316L,

1Cr18Ni9Ti, 430, 440,1008,1020,20NiCrMo, 42CrMo4 and non-magnetic stainless steel.

Sand Casting:Malleable Iron,Ductile Iron,Gray Iron |

Csrex is a group enterprice, has one steel foundry, one iron foundry and one forging factory. She is your reliable source for Ductile iron, Alloy iron, Gray iron, and Heat-resistant steel, Alloy steel and other metal products. The company's policy is to produce castings/forgings to meet your individual requirements, as well as monitoring each stage of production to guarantee high quality. We pour to different international standards. We can offer material analysis, heat treatment, non-destructive testing, proof or full machining. Quality and Service is our emphasis!

Castings / forgings are from 0.5kg to 300 Ton.

Our monthly capacity is over 800 tons, with total occupied land size as 8000m3. Its products cover different industries like automobile, construction, machinery, ship and etc. Over 90% of its products are far sold to dozens of countries and regions such as British, German, France, US, Japan, south Korean, Australia.

Main products:

1. Large wind turbine parts such as: Rotor hub, Base frame, Motor housing, Nacelle, Torque support, Planet carrier, Bearing housing, Gear housing, Sealing cover and other iron castings & parts.

2. All kinds of grey cast iron, ductile cast iron, carbon steel and low alloy steel, heat-resistant and wear-resistant and corrosive-resistant special cast iron and steel castings, castings & parts of pumps, valves etc

Essential Inspection facilities or methods:

Photovoltaic direct-reading spectrometer, Carbon & Silicon thermal analyzer, Chemical analysis, Metallographic Analysis, Mechanical properties testing, Casting Dimension inspection and 3D(three-dimensional) measuring instrument for the part's dimension check, Moulding sand testing, Magnetic particle Testing(MT), Ultrasonic Testing (UT), Dye penetration testing, Hydrostatic Testing, etc.

Our factory is only 40 Kilometers from Qingdao seaport and only 40minutes from Qingdao airport by car, wish your visiting to our factory.