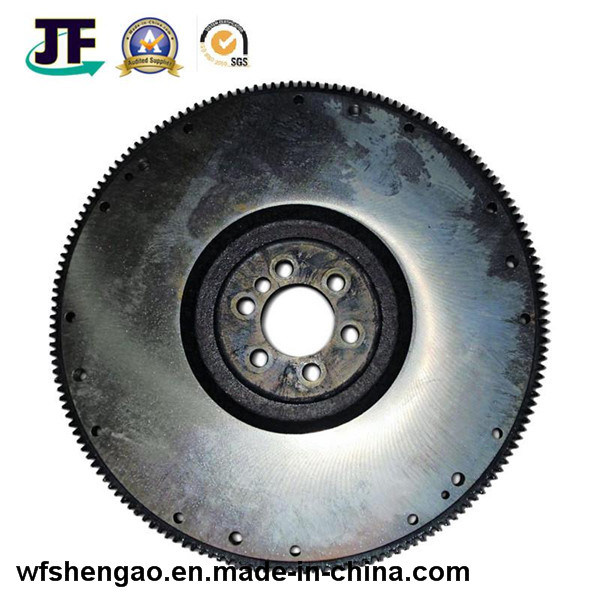

Spin Exercise Bikes Cast Iron Flywheel with High-accuracy

1) Material: ductile iron/ grey iron

2) Weight: 0.1KG-300KG

3) Make products exactly according to your samples or drawings

4) OEM service is available

5) Very rigorous quality control

6) Customized products: different types

7) Process: sand casting

8) Surface treatment: painting, plating,polishing,power coating etc.

9) Cast iron flywheel

Large flywheel ring gear is manufactured in Segments. A large flywheel ring gear is divided into 8-16 segments, which are joined by bolts. The segment length typically varies between 0.8-1.6M. Short segments are usually used for versatile precision machines.

Large flywheel ring gear is extensively used in most of the mills and kiln drive system. A large flywheel ring gear is one of the highest cost components in the entire drive assembly and has a very big diameter with high precision finish. The large flywheel ring gear has a high efficiency and its overall life depends upon the proper lubrication and alignment.

Manufacturing Capacity: Outside diameter from 1,000mm to 14,000mm . Unit weight max. reaches 300 tons.

Heat treatment: Excellent heat treatment is available.

Machining: The large flywheel ring gear is machined by advanced equipments.

Quality control: We have a mature QCP control system for guarantee excellent quality.

Inspection: NDE/NDT, UT, RT, PT are available.

1. Drawing control

Confidentiality-Be confidential to the customers'drawings.

Check- Technician checks the drawings and confirms dimensions

Confirmation - Confirm the production process & inspection process according to the drawings

2. Mold making control

Inspect the dimensions and material according to drawing.

Send test reports and photos to customers.

3. Raw Casting control

Produce according to the production tracking form

Use advanced inspection equipments to ensure internal quality of the product.

Check the test bar and record relevant information to each bulk.

Send the photos and test data of each step to customers.

4. Machining process control

Produce the samples according to the confirmed casting process.

Train the relevant staff before producing according to the machining and inspection process.

Our inspector will track the quality and time of the products during producing. Any problems on quality and process must be feedback to our customers.

Do the finial inspections to the products and send the relevant data and finished product photos to the customers.

5. Packing and Delivery control

Determine the size & material of the box according to the shape & number of products.

Taking different anti-rust protection to products according the delivery time

Put dimensional reports, chemical & mechanical documents, test bar and photos into the packing box

Send the photos of whole packing process to customers.

We are manufacture which mainly produces pump parts, valve parts, cylinder parts, tractor parts, lathe body, furnace parts and so on. We can also supply you other castings according to your requirements.

We promise to supply you perfect design, professional quality control, competitive prices and excellent after-services

Flywheel

Process:

Our Service

1.We are manufacturer, we have Well and High Quality Control

2.Prompt Delivery

3.Customer's Design and Logo are Welcome

4.Competitive Prices directly from factory

5.Small Order Acceptable

6.OEM / ODM Accepted

1. Q: Why choose Shengao product?

A: We shengao have our own plant-- Weifang Shengao machinery Co.,Ltd, therefore, we can surely promise the quality of every product and provide you comparable price.

2. Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

3. Q: Do you provide customized forging products?

A: Yes. Customers give us drawings and specifications, and we will manufact accordingly.

4. Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc..

If there's anything I can help, please feel free to contact with me.

WeiFang Shengao Machinery Co., Ltd is located in WeiFang the famous city in China and the world center of kites. It is 140 kilometers far away from Qingdao port, the transporation is very convenient. Our company use the location advantages of ShanDong province to integrate resources so that we can processing according to the drawings of customers. We mainly undertake the casting parts, machined parts and other products. Our Import and Export Department have many years experiences of foreign trade, products are mainly exported to the United States, Denmark, Italy, Russia, Australia etc.

Over the years, company adhere to the guideline for management of "Quality first, Reputation first, Delivery just-in-time, Price best". We will try our best to improve the technical level and perfect the enterprise management. Our company will depend on superior quality of products and sincere service to cooperate with dometic and overseas, new and old customers and establish eternal friendship to create a bright future.