QUOTS VARIE BASED ON THE REQUIREMENTS

OF DIFFERENT COMPONENTS

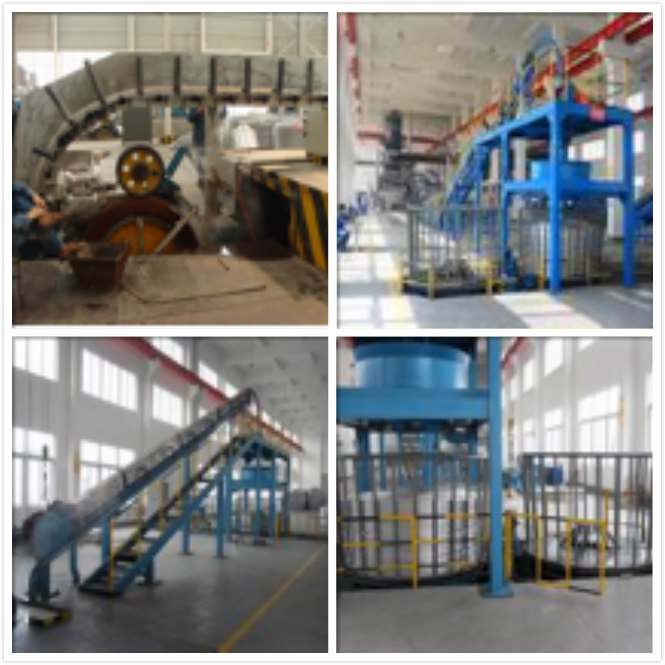

ALUMINUM ALLOY CONTINUOUS CASTING & ROLLING LINE

1. Application and Composition:

The machine adopted new four wheels continuous casting machine and continuous casting and rolling technology with output rod of ¢9.5mm (Magaluma, Almasilium, Aluminum alloy in 1, 3, 6,8 series). The induction heater ensures the temperature of casting and rolling which can not only cast bar casting and control the heat, but also has the function of automatic feeding and rods stacking stop. Meanwhile, the crawler guaranteed the output of the alloy rod. The arc guiding pipe is in a trolley-guiding construction to reduce the scratch upon the wire rods surface. The rod is coiled by means of centrifugal laying head. On the one hand, the copper rod is preformed before entering the collection basket; on the other hand, the end of rod drops down into the basket automatically in case rod broken. With the car moving accumulator, make the change in order so that it can take up by spooling in dual and coiling continuously. This unit is also produce aluminum rod for electrical purpose.

2. Process flow chart:

Vertical melting furnace →Hydraulic titled holding furnace →Four-wheel casting machine →Front haul unit→ Rolling shear→ Straightener→ Frequency heater→ Continuous mill (with feeding device)→Quench cooling device→ Rear haul unit→ basket down coiler→ Aluminum and magnesium rod

3. Main Technical Specifications

3.1 Four-wheel Casting Machine

Four-wheel casting machine consists of upper tundish under gravity flow control device, casting wheel and its gearing, pinch roller, steel tape with oil applicator, guide-bridge, tension wheel, cast bar extractor, inner and outer coolers and steel tape.

The molten aluminum flows to the upper tundish through the holding furnace which managed by the floating plug for gravity control. It cast level from under tundish to the inner mold made by casting wheel and sealing steel belt. The section of the casting wheel is like "M", and cools from three ways to make sure the compaction and uniformity, but the cooling can roll out easily from the casting wheel which adjust the cooling water and maintain the equipment. All the nozzles are stainless steel with pressure display. The steel belts are adjustable hydraulic tensioner. There is an inner cooling system in the supporting axle of casting wheel. With the water pressure 0.2~0.5MPa, the cooling water sprays to the surface of the casting wheel. There are three sections of water cooling piece each in inner and outer cooling system. The molten aluminum then gradually comes into aluminum cast bar.

Cast bars which have been solidified on crystal rounds are excised by cast bar retractor, and sent along the bridge approach by the front traction. Pinch rollers press steels on the crystal rounds to prevent leakage of molten aluminum, with a guide wheel unit to adjust and change the strip direction. The tension of the strip is adjusted by pulley devices to maintain a certain tension. In order to facilitate stripping of aluminum cast bar, continuous casting machine is also equipped with steel oiled unit. As the entire process is continuous, so you can get a large length of the cast bar.

Diameter of casting wheel | ¢1600mm |

| Cross section of cast bar | 2400mm² |

| casting rate | 7.6-15m/min |

Rotating speed of casting wheel | 1.66~3.3r/min |

Power of motor for casting | 5.5kw

motor speed by frequency control |

Pressure of cooling water to casting wheel | 0.2~0.5Mpa |

Cooling water volume | 100t/h(inner 40t/h,outer 30t/h,side 30t/h) |

Cooling water temperature | 15-45ºC |

Cooling water requirements | PH7-8,CaO20-50PPM,0.8mm,mg/e,GB1576 |

3.2 Front hauling machine & Rotary cutter

Motorized pinch rollers to ensure the aluminum cast bar enter the shearing area quickly.

| Motor | 5.5KW

Motor speed by frequency control |

Diameter of haul-off wheel | Upper wheel: 200mm

Lower wheel: 280mm |

The motor for rotary cutter hauls the reducer to drive the cutter. Both cutters contain two blades. The speed of tool nose is closed to the moving speed of casting cast bar. The upper and below cutters slit it in pair.

After the cast bar draws forth, the rotary cutter cuts it into parts if the cast bar is not in good quality.

When the cast bar meets the condition for rolling, the rotary cutter stops working and the cast bar starts rolling. If there is any problem, the rotary cutter will start automatically to cut the cast bar into parts before it is pulled away.

Motor: 15kw

3.3 Motorized straightener

It has five wheels, three fixed wheels above, two driving wheels below arranged in intervals. Cylinders control the wheel to go up and down through electrical control.

| wheel number | Upper wheel 2

Lower wheel 3 |

| motor | 5.5 kw

frequency inverter for motor speed |

3.4 Induction heater (At user's option)

Technical parameters

| Power rating | 300kW |

| Inductor voltage | 700 V |

| Material for heating | aluminum/alloy cast bar |

| Size of material for heating | >2300mm² |

| Running speed of aluminum cast bar | 10--13m/min |

| Temperature of incoming material | 400-440ºC |

| Temperature rise | 80-100ºC |

| Productivity | 4.5t/h |

| Cooling water | ≥0.2MPa |

| Temperature of inflow | 5~35ºC |

| Temperature of outflow | <55ºC |

| Water quality | PH6~8 |

| Alkalinity | ≤10 |

| total content of solids | ≤250/ mm/l |

| water consumption | 15/ T/H |

| Inlet voltage | 380V |

| Inlet frequency | 50HZ |

| Voltage of control of circuit | 220V |

| weight of furnace | 1000kg |

| size | 2200×1040×1400mm |

Aluminum cast bar induction heating apparatus consists of grate, two inductors , three supporting scroll wheels(high-temperature bearing), four compensating condensers, inlet water distributor, back flow water collector, connected copper bar and burden measure temperature head. Two inductors are series connection. The power supply only loads for one.

Aluminum cast bar does not hit the stainless steel inner container of the inductor when entering the hearth which can shorten the length of the resonant tank to avoid waste. The shell of the condenser is insulation, so it need to put on the insulate stand.

There are fourteen routes of cooling water. Each inductor has five routes of cooling water, ten in all. Each capacitor gets through one route, four routes in all.

Measure temperature head installed in the entrance and exit of the hearth. Temperature measuring system applies light-guide fiber. It connects to the temperature control cabinet by the shielded wire on the scene,

There is an electric hydraulic pressure gauge with connector in the main inlet tube of the water cooling system. The water temperature relay is installed in the backwater pipe of the inductor in order to supervise the water temperature of all the branches.

Furnace body can be moved entirely. Another pair of supporting wheel in the furnace stand will support the casting aluminum billet after the furnace is moved.

Electric control:

The heating furnace used KGPS300-0.4J intermediate frequency power supply. Manual control for power adjusting, detail description is seen from the instruction. Control circuit uses single-phase AC 220V, 50Hz. The supplier needs take action to prevent electromagnetic interference. Low Voltage Apparatus is Schneider and Shanghai electric product. The electric control cabinet is whole sealing, and the wire arrangement inside is work under IEC standard.

3.5 Continuous rolling machine (including motorized feeder)

The continuous rolling machine consists of 15 stands which are of three-roller type, with nominal diameter of roller in ¢255. The pass pattern is one arc, three triangles and a circle. Motorized drive applies a coupling to connect DC 400kw motor with transmssion gearbox. Transmission box and the stand joints both have security tooth type coupling. When it is overloading, the sheer pin will be cut to avoid accident. Every stand has inlet, outlet lead pin. Odd ones are rolling type and even ones are gliding type. The roller stands use different half type shim for adjusting so as not to screw out four fixed bolts(adjustment range:0.1-1.00mm). The pass pattern is adjusted according to the plug gauge. As it is required that 0 place pass, but not pass even plus 0.1mm. The rolling gap is 0.866mm.

| outlet rod diameter | ¢9.5(±0.10) |

| stand number | 15 |

| nominal size of roller | ¢255mm |

| transmission ratio between two neighboring stands | 1:1.25 |

| Max. final rolling speed | V=7.5m/s |

| main motor power | 400kw(DC) |

3.6 lubrication and cooling system

1) Lubrication

Thin oil lubrication system used in transmission gear and bearings from the gearbox.

| two oil pumps | ZCY-18m³/0.36(,)

one for stand-by, to be provided by user |

| Max. flow | 18m³/h |

| working pressure | 0.35Mpa |

| Type of motor | Y132M2-6 5.5kW |

| oil temperature | ≤45ºC |

| one oil tank | V=4.2m³ |

The lube oil in thin oil lubrication system gearbox goes through the oil pump by the 3.5m³ oil tank to the inlet pipe from the back of gear box. It works in three routes to the gear box and then enters the nozzle by the branch pipelines.

The gear splashes the lube, and lubricates directly to the rolling bearing with the help of the branch pipelines 's red copper sleeve and the oil hole of the upper side of the bearing block.

2) cooling system

Emulsion is applied in lubrication and cooling of the stand.

two emulsion pump | 22kw

one for spare supplied by user |

| Max. flow | 100m³/h |

| working pressure | 0.3-0.5Mpa |

Emulsion flowage can be adjusted through the valve switch, and the emulsion is stored in the pipe which lies in the upper side of the drive gear box. It goes into the guiding device through the top and two sides of the stand. The emulsion flows back into the emulsion pool via the return pipe of the base to the return tank.

3.7 Quenching cooling system and double frame take-up device

1) Quenching cooling system

Quenching cooling system is stainless steel, quick-cooling, and pressure can be adjusted in every stage with pressure meter which ensures quality. Also a stair for maintenance is supplied.

| way of quenching | 8 8 stage |

motor for quenching pump | 18.5kw (11)

One in use, another one for stand-by |

2)

The machine consists of operation desk, gathering device, rolling guide device, coiler and take up device.

Aluminum rod rolling guide device gathers double actively, and the speed regulation runs with the rollers. The speed can be adjusted.

The running roller of the rolling guide device makes up of R1000 arc, installed and gathered the upper side of the device which can minimize the damage of aluminum rod. The coiler is working by elastic coupling driving the worm wheel reduction gearbox, and then swings the rod to be coiled. The coiled diameter can be changed through the motor speed.

The operation desk is composed of terrace and stairs which used to maintain and install the device.

| outlet diameter | ¢9.5 |

| haul-off speed | 7.94m/s |

| motor for rear haul-off | 7.5kW frequency inverter |

| Spooled diameter | ¢2300mm |

| motor for spooling | 4 kW frequency inverter |

| staggered winding | 2.2 kW frequency inverter |

| weight of rod | 2000kg |

3.8 Electric control and principle summarize

1) DC: EUROTHERM 591

2) PLC: Siemens S7-200

3) The speed of casting wheel is controlled by a potentiometer called "casting machine set-up". The wheel is driven by a frequency control device, and the speed signal processing is then given by the first traction drive, rolling mill drive.

Traction motor before adopts frequency inverter timing driving. Its option consists of stand-alone and linkage. When it's linkage, the speed's signal is given by crystallization wheel drive device. When it comes to stand-alone, the speed would be given by casting traction work station to adjust potentiometer. Under these two ways, launching and stopping signal are controlled by control cabinet.

Stand motor's speed and prime mover are by European dc. Its option consists of systematic linkage, rolling linkage, stand-alone. Under systematic linkage, the speed's signal is given by crystallization wheel drive device. Meanwhile, rolling mill control cabinet's budge potentiometer does the micro adjustment. When it comes to rolling linkage, the signal would be adjusted by rolling mill's potentiometer. Under rolling linkage and systematic linkage, rolling mill's speed signal is controlled by traction drive after. The signal will be due to control cabinet's potentiometer.

Traction drive after employs frequency inverter control device drivers. Its option consists of stand-alone and linkage. When chosen linkage, its speed is given by rolling mill drive device. It would be adjusted by accept line work station. These two ways are under control cabinet with its launching and stopping signal.

The pole motor is driven by a speed controller.

To ensure the normal operation of continuous casting and rolling, continuous casting cooling water pumps, mill pump system, emulsion system, electric control adopt "with a prepared" approach.

4) When the machine is running, casting machine, the former traction, rolling mill, the later traction, drying machine, plum received frame choose linkage method. Under the harmonization of PLC, all parts work together.

When the mill fails, the mill automatically stops, clamps former traction, starts rolling scissors and the rings sound and light alarm. After emergency services, the mill continues to operate normally.

When the mill pump, emulsion, water pump failure, it rings sound and lights alarm immediately and starts the standby pump. Automatic elimination of failures ensures the normal operation of the mill.

5) Main electric elements

PLC: Siemens S7-200

AC motor: Eurotherm

Relay: Siemens (Made in China)

HMI: Color 10" (Made in China)

AC YASKAWA,JAPAN

Proposal and Quotation for

Furnace Set for Making Aluminum Alloy

1,Technical Requirements:

1.1 Product: Aluminum alloy rod

1.2 Fuel: Natural gas

1.3 Workshop: to be determined

2, Proposal for Refining Furnace: 12-ton Twin-chamber Continuous Melting Furnace

2.1 A holding chamber (front furnace) will be added to the existing shaft furnace;

2.2 Objective One: To bring up the capacity of the furnace to 12 tons, to have enough water storage capacity so that the holding furnace will not burn off fire during casting operation, and the designed melting speed can get close to the average melting capacity, thus making it possible to reduce energy consumption, simply operation, and prevent freezing at the spout and in the launder;

2.3:,30min(2h),,,,,,,,(1.5-2h),,;

Objective Two: To have enough capacity for water storage, from the melting furnace to the holding furnace molten aluminum can be transferred within 30 minutes, thus shortening the previous time, which was about two hours that resulted in decrease of temperature, suction of air and inclusion of slag. At the same time, enough time is left to the holding furnace to raise the temperature, normalize and refine the metal, clean the slag, remain standstill, and clean the furnace for about 1.5 to 2 hours. So deficiency in the old type of furnace is compensated and quality of aluminum liquid is improved;

2.4:,670ºC740ºC,,;

Objective Three: As burning load is concentrated in the front furnace, temperature of the molten aluminum is increased from the previous 670ºC in the old shaft melting furnace to 740ºC, so that it's possible to keep the launder free from freezing and shorten the temperature rising time during the holding process;

2.5:15%,(70%),,,,(25%);

Objective Four: Saving energy by more than 15%. As the afterheat of the fume from the front furnace during the temperature-rising is all spent on preheating the aluminum ingot and melting (thermal efficiency at about 70%), plus the energy saved from the concentrated transfer, the afterheat will be emitted in the preheated air if the holding furnace carries out temperature rise, losing about 25% thermal efficiency;

2.6:,,,.

Objective Five: Reducing heat loss of aluminum. After a certain amount of aluminum is kept, most of the aluminum ingots are submerged in the molten aluminum and then melt into liquid thereinafter. This apparently reduces the heat loss a lot.

3,:

Proposal for Holding Furnace: Two Sets of Round-shaped Holding Furnaces

3.1:10,,,,,,,,,,.

Type and size of furnace: Two sets of 10-ton tilting round-shaped holding furnaces that work in turn to supply molten aluminum to the continuous casting and rolling process. When one is pouring molten aluminum to the casting machine, another one cleans the furnace, takes in the molten aluminum, raises the temperature, mixes alloy, refines the liquid, cleans the slag and remains standstill.

3.2:

Advantages of tilting holding furnace:

3.2.1,;

It keeps the molten aluminum in the furnace on the same level with the liquid in the launder, thus reducing the possibility of slag inclusion and air suction due to turbulence during pouring;

3.2.2,;

Top layer of molten aluminum at a higher temperature is discharged first, which is conducive to casting higher temperature molten aluminum as per the process requirements;

3.2.3,.

Molten aluminum is poured completely so that the alloy elements can have better homogenization.

4. :

Configuration

4.1 :

Furnace body

4.1.1 12T(δ1216#,),,,,,;

The 12-ton twin-chamber continuous melting furnace includes bottom plate made from δ12 steel plate, 16# channel steel, and H-steel, hinged door, charging hopper, hot air furnace lining of shaft furnace, spout, hot air duct and standard connectors;

4.1.2 10T(δ1620#,),,,.

10-ton round-shaped tilting holding furnace includes bottom plate made from δ16 steel plate, 20# channel steel, and H-steel, hinged door, spout, hot air duct and standard connectors.

4.2 :

Furnace door and opening and closing system:

4.2.1 12T780×550;

12-ton twin-chamber continuous melting furnace is equipped with two 780×550mm cast iron hinged doors;

4.2.2 10T780×550;

10-ton round-shaped holding furnace is equipped with one 780×550mm cast iron hinged door;

4.2.3 :,,.

Sealing: Grooved castings are used around the furnace door, in which high temperature fiber cellucotton is inlaid to keep its sealing for a longer service life.

4.3 :

Burner

4.3.1,,800ºC,,,,,;

Taking natural gas as the fuel, high temperature burner is provided with lining castable suitable to 800ºC hot air and the burner will not be burned down. It is placed in a tangential way so that the furnace gas circulates strongly, temperature difference in the chamber is small and thermal efficiency is high;

4.3.2 12T1220()100();

12-ton twin-chamber continuous melting furnace is equipped with one set of 2.2 million kcale burner with automatic control and one set of 1 million kcal high temperature burner, with manual control;

4.3.3 10T1100.

10-ton round-shaped tilting holding furnace is equipped with one set of 1 million kcal high temperature burner.

4.4 (≤800ºC):

High temperature natural gas burner and automatic control system for burning (air preheating temperature ≤ 800ºC):

4.4.1 ,,,,,;

Automatic control system for natural gas burner is composed of igniting pistol, igniting transformer, igniting solenoid valve, flame-size solenoid valve, emergency breaking solenoid valve, violate flame detector and electric automatic control cabinet;

4.4.2 ,,,,,;

To be provided to the high temperature burner, used in the melting furnace and holding furnace to perform control over automatic ignition, flame detection, constant temperature control of flame size, gas supply emergency cut-off for accidental flame-off, and warning, etc.;

4.4.3 ,;

Frequency converter is used to adjust the air volume, flame-size solenoid valve to adjust the natural gas volume;

4.4.4 :;

Temperature control: To perform constant temperature control over the burner for flame size as per the set temperature;

4.4.5 :;;

Pneumatic lifting temperature detecting mechanism: When thermal couple is lifted, it controls the gas air temperature; when it is lowered down, it controls the temperature of molten aluminum;

4.4.6 :,;

Fume hood exhaust valve and flame-size burner interlock: automatically shifts to small flame, fume hood exhaust valve at furnace door is open;

4.4.7 :;

High temperature fume valve at the furnace body vent or top cover interlocked with air blower: Only when high temperature fume valve or top cover is open, can the air blower start running;

4.4.8 ;

Shift function between manual and automatic control;

4.4.9 800ºC;

High-temperature and automatic control system are applicable to air preheating temperature below 800ºC.

(GRYQ220/100)

List of Equipment

(with Burner Type GRYQ220/100 as an Example)

No. |

Description |

Type |

Quantity |

Remarks |

| 1 |

Igniting solenoid valve | 0.02Mpa-DN15 | 1 set |

Honeywell |

| 2 | ,

Slow-motion solenoid valve | 0.02Mpa-DN40/32 | 2 sets |

Honeywell |

| 3 |

Emergency breaking solenoid valve | 0.02Mpa-DN50/40 | 1 set |

Honeywell |

| 4 |

Flame detector |

| 1 set |

Honeywell |

| 5 | //

Igniting transformer, electrode, pistol |

| 1 set |

Made in China |

| 6 |

Manual gate valve | 0.6Mpa-DN15+40/32 | 1+2 sets |

Made in China |

| 7 | ()

Control cabinet, including air blower frequency converter |

| 1 set |

Made in China |

| 8 | GRYQ220/100

High-temperature burner | ≤800ºC

Air temperature | 1 set |

Made in China |

5. :

Fuel Supply System

5.1,;

Natural gas is used as the fuel. So fuel storage and supply system before the burner shall be the User's responsibility;

5.2 ,,,,,,.

If automatic control is needed, the automatic valve shall be the Supplier's responsibility. The general valve, pressure regulating valve, flow meter, pressure regulating station and pipelines shall be the User's responsibility.

6. :,,,.

Mode of molten aluminum pouring: An inlet is set in the wall of the holding furnace and a transitional detachable launder is set between the melting furnace and the holding furnace, through which the molten aluminum flows by itself into the holding furnace due to the difference of level, free from leak.

7. :,,.,,.

Air preheating for holding furnace: The holding furnace is provided with barrel type horizontal air pre-heater, which can preheat air to help burning and reduce energy consumption, and improve thermal efficiency and temperature. The pre-heater is rational structured in material, dust treatment and free expansion so that it can have a longer service life.

8. :

Parameters of Natural Gas

8.1 :

Gas Volume

a. :320(220+100)(100%),100+100(50%);

Load on burner: 3.2 (2.2+1) million kcal (operation rate at 100%) for melting furnace; 1+1million kcal (operation rate at 50%)

b. :

Confirmed momentary consumption of natural gas as per configuration of burners for one set of furnaces:

=320+200×50%=420÷0.84=500Nm³/h;

c.

Momentary consumption of natural gas as per production capacity of one set of furnaces

=5t/h×65m³/t=325 Nm³/h≈350 Nm³/h;

d.

Maximum daily consumption of natural gas

=output×65Nm³/t=100t/day×65 Nm³/h =6500Nm³/day;

e. :

Confirmed maximum momentary consumption of natural gas:

350 Nm³/h (natural gas supply system ≥450 Nm³/h);

:

Confirmed maximum daily consumption of natural gas:

6500 Nm³/day (natural gas supply system ≥8000 Nm³/day);

f. 120%-150%,≥450 Nm³/h,≥8000 Nm³/,,,(),.

When making the natural gas supply system and plan for consumption of natural gas, a margin of 120%~150% must be reserved, i.e. ≥450 Nm³/h, ≥8000 Nm³/day. This margin is based on the development of the factory, possible increase of consumption, and restricted supply in case of shortages of natural gas, as well as the initial installation cost as per cubic meter.

8.2 :

Pressure of natural gas:

8.2.1 0.2-0.4Mpa;

Pressure in the incoming mains shall be 0.2~0.4Mpa;

8.2.2 :0.1-0.15 Mpa();

Pressure of the mains within the factory after the gas station is set at: 0.1~0.15Mpa after primary pressure regulation;

,;

This pressure must be higher than the pressure at each gas consuming point in order to meet requirements of pressure at the location;

,,;

This pressure should better be on the higher side in order to save costs for pipeline in the factory and the secondary measurements and flow;

8.2.3 :,;

Pressure at each gas consuming point: to be provided with secondary measurement and secondary pressure regulation for the set of furnaces as per the requirements on the burning system;

:10-20Kpa(0.01-0.02Mpa);

When furnace set is under automatic control: operating pressure of burner 10-20Kpa (0.01-0.02Mpa) is adjustable;

:30-90Kpa(0.03-0.09Mpa).

When furnace set is under manual control: operating pressure of burner 30-90Kpa (0.03-0.09Mpa) is adjustable.

9. :

Bottom-placed permanent magnetic stirrer:

:YJD-1000A;

Type: YJD-1000A;

:250mm≥700GS;

Magnetic field intensity: ≥700GS at 250mm away;

:720ºC≥20/.

Rotating speed of molten aluminum: center ≥ 20rpm when molten aluminum at 720ºC.

9.1 YJD-1000A;:

One set of bottom-placed permanent magnetic stirrer (YJD-1000A) and tracks provided to the two holding furnaces: The stirrer will have the following effects on the melting of aluminum alloy and scraps:

a. ,,;

A shorter melting time, higher homogenization of the alloy elements, and so segregation can be prevented;

b. ,,;

Smaller temperature difference between the top and lower layers of the molten aluminum, over-burning can be avoided but higher quality of cast aluminum can be achieved;

c. ,,.

Smaller heat loss, quicker melting speed, and more energy is saved.

9.2 ,,,;

Stirrer is provided a motorized lifting system, motor pulling system and guide track, air cooling system, and over-temperature protection system;

9.3 :

Stirrer control system includes:

a. (11Kw),(1.5Kw),(0.75Kw),(1.1Kw),;

Frequency-variation speed regulation and forward and backward running control (11kW), motorized lifting (1.5kW), motorized pulling (0.75kW), cooling air fan (1.1kW) on and off, temperature measurement and over-temperature alarm;

b. ,,,.

Two thermal couples - one for over-temperature alarm and another for over-temperature alarm and automatic lifting system to lower down the stirrer and stop the main machine from running.

10. :

Miscellaneous:

10.1 ,,.,..,.

When the furnace tilts, position of the spout remains unchanged, which is the rotating center of tilting, and it's slightly lower below the level of aluminum liquid so as to keep the oxide over the liquid aluminum relatively stable. The spout is in such a construction that makes it easy for slagging. Bearings are placed at the spout cover and provided with balancing weight.

10.2 :≥100;

Main technical data of hydraulic cylinder for tilting operation: thrust force from cylinder ≥100 tons

a. φ273mm(φ220mm);

Outer diameter of oil cylinder at φ273mm (piston rod at φ220mm);

b. 14MPa;

Working pressure of hydraulic system at 14MPa;

c. 25MPa.

Rated pressure of hydraulic pump at 25MPa.

10.3 :

Hydraulic components are foreign brands;

a. MARZOCCHI;

Hydraulic gear pump is MARZOCCHI;

b. VICKERS;

Explosion-proof valve is VICKERS;

c. REXROTH;

Solenoid directional valve is REXROTH;

d. KAMUI;

Cooler is KAMUI;

e. ATOS;

Proportional velocity regulating valve and velocity regulating valve are ATOS;

f. ,,,,HYDAC.

Shuttle valve, one-way valve, overflow valve, electromagnetic ball valve, manual ball valve are HYDAC.

10.4 :

Window for permanent magnetic stirrer at the bottom of holding furnace:

a. ,;

The functioning window of the permanent magnetic stirrer and the passage bottom are made of stainless steel; the magnetic stirrer window bottom is made from fiber insulating material and wash-resistant lining material;

b. 12mm,(DKS-901).

12mm stainless steel plate and reinforcement plate are used, and corundum low cement castable (DKS-901) is used as the lining.

11. :

Proposal for Air Preheating and Utilization of Afterheat:

11.1 :

Twin-chamber continuous melting furnace

11.1.1 φ1300×H3400:,.

A φ1300×H3400 vertical hot air furnace pipe is provided for higher thermal efficiency and lower energy consumption

a. :φ1300,3400;

Main features: inner diameter of the upper section of vertical furnace changed toφ1300 and height of hot air furnace pipe at 3400mm;

b. :,;

Preheating aluminum material: When there is aluminum material, the upper section preheats the material as the main job, and preheat the air as the secondary job;

c. :200-300ºC,,,;

Preheating air to help with burning: preheat the air up to 200~300ºC to bring up the temperature of flame, melting speed, and temperature of molten aluminum at discharge, thus reducing energy consumption;

d. :,;

Prolonging the service life of vertical furnace: shortcomings of the lining of cast iron bricks and the lining of refractory bricks not resistant to high temperature and wear;

e. :,,;

Scope of supply: main body of hot air furnace pipe, air cooling protection system, hot air pipeline system;

f. :16mm(SUS321+SUS202),

φ1300.

Description to material: inner pipe and inner side of flange is made from 16mm (SUS321+SUS202) heat-resistant stainless steel in a diameter ofφ1300

11.2.

Round-shaped tilting holding furnace

a. ,300ºC;

Tubular horizontal air pre-heater is provided to the holding furnace at a maximum temperature of 300ºC;

b. ,,.

High-temperature pneumatic butterfly valve is provided at the fume outlet, which closes by itself in case of flame-off in order to minimize heat loss while protecting the pre-heater.

12. :

Fume Exhaust System

12.1780×550;

Two fume collecting hoods in 780×550mm are provided over the furnace door of the twin-chamber continuous melting furnace;

12.2 780×550;

One fume collecting hood in 780×550mm is provided over the furnace door of the round-shaped tilting holding furnace;

12.3,,.

Flange interface is reserved for fume collecting hood; all fume valves, fume exhaust pipelines and fume purification system are User's responsibility.

13. :1.25T;

Charging Mechanism: a 1.25-ton four track charging mechanism is provided to the melting furnace;

13.1:

Main Features

a. :,,,;

In vertical four-track construction: smooth operation, a big level movement when the hopper moves to the upper position so that the electric elements and steel rope are far away from high temperature on the top, and that aluminum material is emptied smoothly;

b. ;

Hopper is in such a construction that it's suitable for fork lift and overhead travel crane to hoist a bundle of aluminum ingots into it;

c. :,;

Frequency variable dual-speed control: low-speed for hopper to start and empty the material and high speed in the middle section;

d. :,,.

Good safety measures: Locking devices are provided on the top in case of broken steel rope to prevent the charging hopper from falling down; a protection net is also provided for the whole charging system;

13.2 :

Scope of supply

a. ,,,,;

Including guide track, hopper, hoist system, enclosed protection net and anti-falling locking device;

b. :(4.5Kw),.

Control system: including frequency-variable dual speed control of the main motor (4.5kW) and automatic return travel.

14. :

Air Supply System

14.1 (15+7.5Kw),,,,;

Twin-chamber continuous melting furnace includes air blower (15+7.5kW), air valve, cool air pipeline, hot air pipeline, connectors and seals;

14.2 (7.5Kw),,,,.

Round-shaped tilting holding furnace includes air blower (7.5kW), air valve, cool air pipeline, hot air pipeline, connectors and seals.

15. :

Control System

15.1 :1(15+7.5Kw),,;

Twin-chamber continuous melting furnace: including control of 1 set of main air blower (15+7.5kW), measurement of temperature in the hearth, and measurement device with pneumatic lifting;

15.2 :(7.5Kw),,,;

Round-shaped tilting holding furnace: including control of main air blower (7.5kW), measurement of temperature in the hearth, temperature measurement device with pneumatic lifting, pneumatic lifting of furnace door and compression control and so on;

15.3:(4.5Kw),,();

Control of charging hopper: frequency-variable dual-speed control of motor hoist (4.5kW), automatic return travel, over-limit alarm for upper limit and lower limit, and over-limit locking;

15.4 :(11Kw),(1.5Kw),(0.75Kw),(1.1Kw),.

Control for stirrer control: Frequency-variable speed regulator and forward and backward running control (11kW), motorized lifting (1.5kW), motorized pulling (0.75kW), cooling air blower (1.1kW) on and off, temperament measurement and over-temperature alarm.

16 :

Molten aluminum temperature-measurement device with pneumatic lifting

,();().,20.

Thermal couple is placed in carborundum protection pipe; when it's up, it measures and controls the temperature of furnace gas; when it's down, it measures and controls the temperature of molten aluminum. As it's fragile, its service life is normally around 20 days.

5. :

Main Economic and Technical Data

1. :,≥8400Kcul/Nm³;

Fuel: natural gas is used as the fuel, whose low-order caloric value≥ 8400Kcul/Nm³;

2. ,:

When the furnace enters a thermal balancing state and reaches the rated output capacity and can produce continuously under the following conditions

No. |

Description | 12T

12-ton twin-chamber continuous melting furnace | 10T

10-ton round-shaped tilting holding furnace |

| 1 |

Furnace capacity | 12T+10% | 10T+10% |

| 2 |

Melting ratio | 6T/h+10% |

|

| 3 |

Slagging-off ramp by door | 30° |

| 4 |

Arch door dimension | 780×550 | 780×550 |

| 5 |

Opening and closing mode of furnace door |

Hinged cast iron door |

| 6 | /

Slagging-off/operation mode |

By manual operation |

| 7 |

Type of burner |

High-temperature burner |

| 8 |

Power of burner | 220+100

2.2 million kcal+1 million kcal | 100

1 million kcal |

| 9 |

Pressure of natural gas | 0.01-0.02MPa

Adjustable |

| 10 |

Compressed air | 0.4-0.6MPa 1.5m3/min

Per set of furnace |

| 13 |

Stirring speed in the center of top layer molten aluminum |

| ≥20/

20 rpm |

| 14 |

(100%)

Energy consumption in melting and holding (100% solid material | ≤53Nm³/t·Al | ≤12Nm³/t·Al |

| 15 | ()

Net heat loss of raw aluminum ingot (scraps converted into ingot as per market price | ≤0.8%()

≤0.5%

≤0.8% (as per quality of ingot)

Minimum ≤0.5% |

|

| 16 |

Overhaul life of furnace body | ≥4

≥4 years |

| 17 |

Temperature rise in furnace wall | ≤+45ºC,≤+35ºC

Winter ≤ambient temperature+45ºC, summer≤ ambient temperature +35ºC |

| 18 | Power supply | 50Hz±1.5%,380V/220V±10%()

3-phase, 4-wire system |

3. :

Description to Refractory Materials

3.1,(DKS-70M).(LZ55);

Corundum mullite non-sticky alumina castable (DKS-70M) is used as the working lining and the slag level at the bottom of the melting furnace and holding furnace. Grade three high alumina bricks (LZ55) are used for other parts of the furnaces;

3.2(DL-70/60);

Low-cement high-strength castable (DL-70/60) is used for the top of the melting furnace and holding furnace;

3.3(DKS-80);

Non-sticky alumina castable (DKS-80) is used for the hearth and other complex parts;

3.4:(NG-0.8),(NG-0.8,NG-1.3,NG-2.0);

Insulating layer: floating bead insulating brick (NG-0.8), insulating castable (NG-0.8, NG-1.3, NG-2.0) and high alumina fiber felt;

3.5,:(LN-80).

Mortar: special grade high alumina phosphate mortar (LN-80) as lining working layer.

4. :

Steel

4.1 ,;

All steel materials are from genuine suppliers, and no defective material is used;

4.2. SUS316L.

SUS316L is used for preheating inner pipe of the holding furnace.

Situated in the natonal manufacturing base of the heavy machinery, ITO-sin (DeYang) Wire &Cable Equipment Co., Ltd. Is a professional manufacturer for wire and cable equipment.

After a long-term development of technological research, Itosin embodies the capability of developing and manufacturing complete sets of wire and cable equipment. So far, ist main products include 30 kinds of machineries, which involves series of copper, aluminium, alloy aluminum drawing machines, series of copper. Aluminium and alloy aluminium continuous casting & rolling lines, upward casting production line for oxygen-free copper rod, frame strander, tubular strander and so on. These products are not only well sold in the domestic market, but also exported to more than 10 foreign countries, such as Chile, Ukraine, Mexico, Iran, Pakistan, Thailand, Vietnam, Singapore and so on.