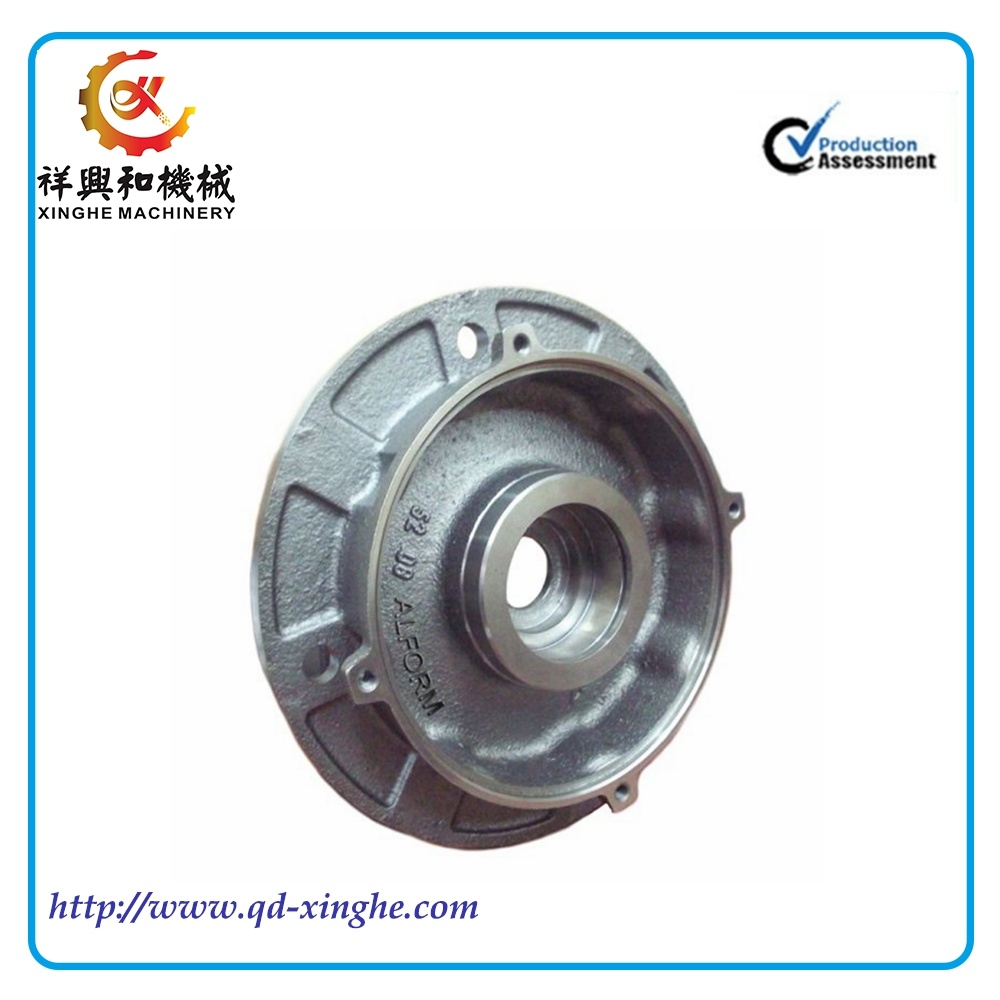

Aluminium Alloy Casting with Sand Casting

1. ISO9001, 2000 Certificate

2. OEM is acceptable.

3. sand casting

4. tapping,milling, grinding

5. aluminum alloy

* Sand and investment casting(precision casting)are all avalable

* Software for drawing: PRO/E, Auto CAD, UG, CAD, PAF and Solidwork 2008 flow analysis

* Further machining work: Turning and cutting, milling, grinding, drilling, reaming and threading

* Surface finish process: Shot blast, chromate plating, power coated and anodizing

* OEM/ODM parts range: Auto parts, electronic parts, furniture parts, home appliance and other industrial uses

* Process: CAD surface, matel processing, surface plating, QC testing and packaging

* Made according to customers' drawing, sepecification or/ and samples

* Castng capacity: 1000tons/per month

Sand casting:

1. Materials: Grey iron GG150, GG250, GG300

2. Casting tolerance: CT9-CT12

3. Standards: GB, ASTM, SAE, ISO, EN, DIN, JIS, BS

4. Piece weight: Al 50 g - 100 kg

5. Steel and iron: 0, 5 - 2000 kg

6. Heat treating: Annealing, discharge, carbonization, tempering, normalization and surface tempering

7. Surface finishing: Grinding, polishing, painting and various coatings.

| Process | Sand casting(Resin sand/Green Sand) |

| Specification | 1.Material: iron/ brass / steel/aluminum

2.Standard: ASTM\DIN\BS\JIS\GB.

3.Surface finish: shot blasting,sand blasting, polishing,painting, etc.

4.Weight: about 1-7000kg. |

| Production facility | 1.Casting facility: Electric furnace, heat treatment furnace,sand mixer,molding machine,shot-blasting machine, sand-blasting machine.

2.Machining facility: CNC machine, NC lathe, ordinary machine tools,linear cutting machine, polishing machine,welding machine. |

| Heat treatment | Annealing/Tempering/Normalizing. |

| Test facility | spectrometer, tensile test machine, hardness test machine,impact tester,CMM. |

| Material | DINGGG40~GGG70 |

| Unit Weight | 0.5kg~300kg |

| Packing | Wooden box with paper box inside |

| MOQ | 100 PCS |

| Delivery Time | 15-20 days for samples.20-30 days for mass production |

| Payment Terms | L/C, T/T |

| Machining | CNC |

| Supply Capacity | 1000 Metric Tons per Month |

| PROCESS | MATERIAL | STANDARD |

SAND

CASTING | Green Sand | Grey Iron, Ductile Iron, Malleable Iron, Stanless Steel, Carbon, Steel, Aluminium, Brass, Bronze | ASTM

BS

JIS

DIN

etc |

| Furan Resin Sand |

| Cold Harden Resin Sand |

INVESTMENT

CASTING | Sodium Silicone (Water galss) | Stainless Steel, Carbon Steel, Special Alloy Steel Bronze, Brass, Aluminum |

| Silica Sol |

| FORGING | Hammer Forging | Stainless Steel, Carbon Steel, Alloy Streel, Brass, Aluminum |

| Die Forging |

| Roll Forging |

| STAMPING MACHINING | STAMPING MACHINING | All metal material |

Qingdao Xinghe Machinery Co., Ltd. Jointly manufactures and exports a variety of casting products for architectural, automotive, mechanical parts. We export to more than 20 countries on 6 continents and have been doing so for more than 10 years.

Our main product line includes sand casting, precision casting, die casting, forging, stamping, welding and CNC machining. Materials vary from grey iron, ductile iron, bronze, aluminum, steel, stainless steel, and so on.

We have a strong and highly efficient R&D team which can design and make OEM/ODM products according to your ideas and samples.

Moreover, in order to ensure the quality of the orders, our independent QC members to carry out strict inspection at each stage:

(1) Incoming material inspection

(2) Inspection of work-in-progress

(3) Finished product inspection

(4) Random warehouse inspections

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own automated casting lines, CNC machining, CMM inspection, spectrometers and MT testing equipment, X-ray.

To benefit from our strong OEM/ODM capabilities and considerate services, contact us today. We will sincerely create and share success with all clients.